/// THE GLOBAL LEADER – CROSS BELT PRODUCTS!

/// XRSciences

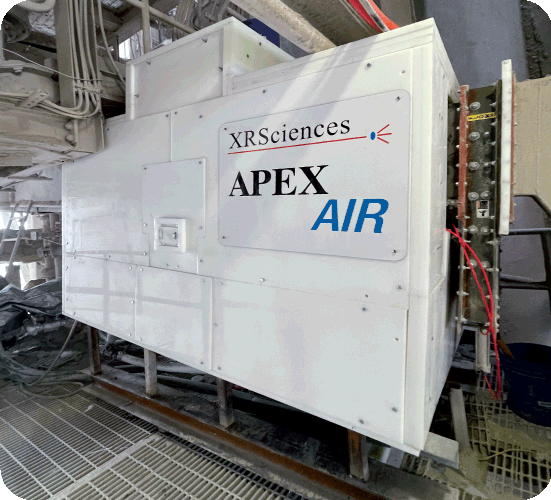

APEX AIR ANALYZER

/// World’s First PGNAA-Based Air Slide Analyzer

/// Measures 100% of the material going through an Air Slide

/// Full Volume Analysis. Not a surface Effect. No layering effect, no sampling bias

/// Designed by Dr. Tom Atwell – inventor of the Cross Belt Analyzer

WORLD’S FIRST PGNAA AIR SLIDE ANALYZER

APPLICATIONS

/// On the ground level, after the raw mill – to optimize the consumption of corrective materials added after the mill such as Fly Ash, Slag, or Dust.

/// On top of the pre-heater tower, to monitor and adjust for avalanches or blockages in the kiln feed silos by providing early warning to kiln control software

/// On top of the kiln feed silo’s, for silo inventory management or to sort raw meal into multiple silo’s

/// After the cement mill, to monitor and control the addition of Gypsum, Syngyp, or Inert Fillers to finished cement

/// On the finished cement as a confirmation sensor to ensure the correct material is being shipped

FEATURES

/// Measures 100% of the material going through your Air Slide, including raw meal, kiln dust, additives

/// Operates continuously on a fluidized, Powdered Raw Meal, Kiln Fee, or Cement

/// Enables complete 100% measurement of material going into your homogenization silo’s

/// Measuring 100% of material – no sampling error, no layering issues, no segregation issues

/// Oxides Reported: CaO, SiO2, Al2O3, Fe2O3, MgO, SO3, Cl, K2O, Na2O, LOI

/// Quality Control Parameters Computed: LSF, SM, AM, Eq. Alkali, C3S, C3A, C2S, C2F, C4AF

/// Enhanced S/N with the new APEX Electronics

/// Connects to any size or shape of Air Slide

/// Detectors mounted in drawers for Ease of Maintenance

/// Developed with Funding from the National Science Foundation

“FATHER of THE CROSS BELT ANALYZER”